Venue: Tylex Letovice, a.s.

Venue: Tylex Letovice, a.s.- Country: Czech Republic

- Years: 2019 – 2020

- Segment: heating of industrial facilities

- Implementation partner: TZB Orlová s.r.o.

Within the scope of a complete modernisation of heating management of a textile factory, the steam-based heating system was replaced with a hot water heating system, ventilation included.

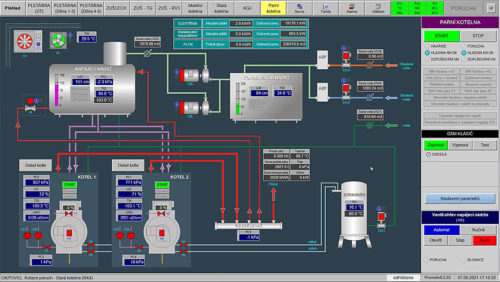

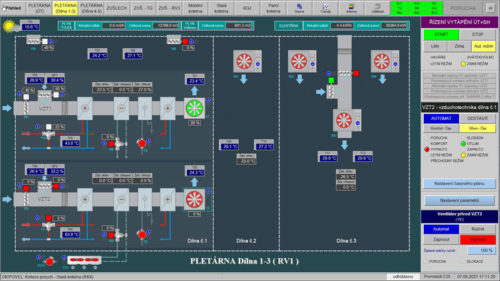

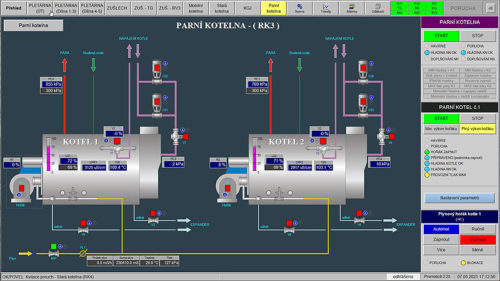

The old steam generating coal-based boiler room was replaced with several gas-based container boiler rooms. They are used to generate steam for technology (heating of industrial machines) and to heat buildings through heat exchangers. The steam boiler room recovers heat from the waste cooling water. The hot-water source is supported by a cogeneration unit that redirects excess energy into the distribution network. Supervision and remote control is achieved via SCADA Promotic.

The project and implementation was financed by Innogy Energo, s.r.o.

Scope of the project:

Hot water boiler room for heating the old boiler room (power of 0.7 MW)

Hot water boiler room for heating the compound (power of 1.5 MW)

Steam boiler room for technical purposes (power of 3.3 MW)

Cogeneration unit for generation of electricity for the distribution network (power of 0.26 MW) with waste heat utilisation

Heating system and ventilation reconstruction – heating and ventilation of the industrial buildings

Water management, treatment and heating of technology water + waste heat recovery

Utillised components:

6× AMiNi4W2, 1× ADiS, 1× AMiRiS99W3, 18× AMRIO (DM-xx) modules