- Venue: Kamenice nad Lipou

- Country: Czech Republic

- Year: 2017

- Segment: food industry, breweries

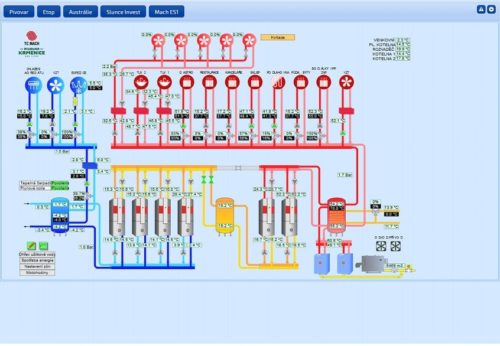

The energy concept of the brewery is based on the use of waste heat for further efficient purposes. The beer production process requires a lot of cooling. The waste heat is a by-product of the process of cooling. This heat is then used as a source for Chameleon thermal pumps made by the company TC Mach.

These thermal pumps use waste heat for further purposes such as:

- Building heating through a floor heating system

- Building heating through a radiator system

- Building heating through air-conditioning

- Service water heating for 45 °C

- Service water heating for 70 °C

Further usage of Chameleon thermal pumps:

- Storage space cooling

- Restaurant air-conditioning

- Great hall air-conditioning

Using waste-heat is a very efficient way to save significant operating costs and simplify the entire energy system. Without the thermal pumps, the heating and cooling system would have to be provided by at least four independent systems.

The total cooling power of a Chameleon thermal pump is 280 kW. Thermal power is up to 400 kW.

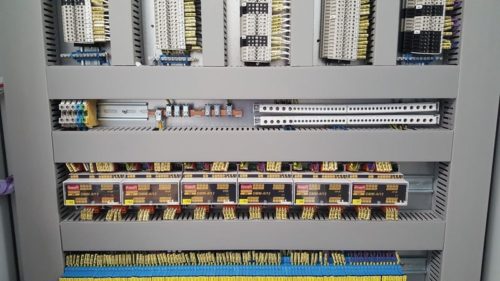

The control system of the entire brewery is built on a platform of several control systems and expansion input/output modules made by AMiT.

Total products used:

- a custom-made control system and terminal Matec TC Mach 7×

- DMM-AI12 8×

- DMM-DI24 3×

- DMM-DO18 4×

- DMM-UI8AO8U 1×

- graphic terminal AMR-OP87 1×